Kunststoffwerk Katzbach GmbH & Co. KG -

Your specialists for EPP, EPS and EPE granulated foam plastics

The development and manufacture of recyclable mouldings from granulated foam plastics is our core competence. We know and understand expanded plastics; we work closely with them on a daily basis.

Since 1972 we have been foaming mouldings from expanded Polystyrene (Styropor®, EPS), polypropylene (EPP), polyethylene (EPE), Neopor® and other materials for leading international companies including those in the automobile manufacture, building insulation divisions as well as for the food, packaging and transport industry.

Continue

Automotive Tier1 Supplier |

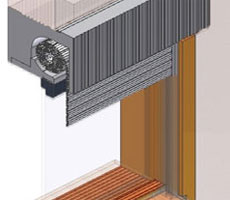

Building insulation around windows and doors |

Technical mouldings and packaging |

||

|

|

|

||

Carriers / logistics systems

|

High degree of heat and noise insulating |

Technical mouldings

|

||

|

In the manufacture of automobiles, Grupor® granulated foam plastics do more than simply protect car passengers. They also contribute to their wellbeing and reduce the car’s dead weight, thereby reducing its fuel consumption and CO2 emissions considerably. Continue |

The German Energy Conservation Ordinance for Buildings (EnEV2009), energy efficiency, economic viability, resource conservation as well as the reduction in environmentally harmful greenhouse gases such as CO2 are the focus of our EPS (Styropor) mouldings. |

Many Grupor® mouldings are used in sports and leisure activities, in the area of heat insulation, in equipment and containers or transport boxes. Continue |

Quality / Certifications

Our company has set itself the market challenge of achieving higher quality standards for products. It is an inherent part of our quality policy and is directly related to our desire to fully meet our customers’ needs.

As part of our corporate philosophy, the company management has set itself the goal of producing products of the highest quality and maximum value in order to gain the desired recognition and loyalty among our customer base.Continue

Kunststoffwerk Katzbach

Environment & Recycling

technology they ensure that heat and cold energy is reduced and actively help to reduce environmentally harmful greenhouse gas emissions. Continue